Content

JUKI-2060 Pick and Place Machine

❙ Introduce of JUKI Pick and Place Machine

The ultra-flexible KE-2060 pick and place machine can place a wide range of components from 0603 and ICs, to odd-form, all at a high rate of speed.

The ultra-flexible KE-2060 can place a wide range of components from 0603 and

ICs, to odd-form, all at a high rate of speed.

■ 12,500CPH: Chip (laser centering/effective tact)

■ 1,850CPH: IC (vision centering/effective tact), 3, 400CPH with MNVC option.

■ One multi-nozzle laser head (4 nozzles) plus one high resolution head (1 nozzle)

■ From 0603 (0201) to 74mm square components or 50× 150mm 0402 (01005) option factory installed.

■ Vision centering system (featuring bottom, side, and back lighting,ball recognition and split recognition)

1 Actual throughput may vary.

2 Please download brochure for details.

❙ Specification of JUKI Pick and Place Machine

| Model | JUKI KE-2060 Pick and Place Machine | ||

| Board Size | M size (330x250 mm) | ||

| L size (410x360 mm) | |||

| L-Wide size (510x360 mm) | |||

| E size (510x460 mm)*1 | |||

| Component size | Laser recognition |

0603 (0201)~□20mm or 26.5×11mm (0402 (01005) optional)*5 |

|

| Vision recognition | 1.0×0.5mm*2~□20mm or 26.5×11mm | ||

| Placement speed | Chip | 12,500CPH*2 | |

| IC | 3,290CPH*3 | ||

| Placement accuracy | Laser recognition | ±0.05mm | |

| Vision recognition | ±0.04mm | ||

| Feeder inputs | Max. 80 on 8mm T/F*4 | ||

*1 Production arrangement starts only after receipt of P/O for E size board.

*2 Effective tact: The chip placement speed indicates an estimated value obtained when the machine places 400 1005-chips all over an M size board.

(CPH=number of components placed for one hour)

*3 Estimated value when using MNVC and picking up components simultaneous with all nozzles.

*4 In addition to matrix tray changer, max 110.

*5 Please ask for details on 0402(01005) placement.

❙ Customer factory

Shenzhen ETA Technology Co., Ltd. Expert in Making Customized High Quality SMT LED Pick and Place Machine, SMT LED Reflow Oven, SMT LED Stencil Printer, SMT Production Line, LED Assembly Line With More Than 23 Years Experience.

Our Goal is to Provide Customers With the Best Service Possible and to Produce Excellent Quality Products That Will Meet or Exceed Your Expectations.

Successful Experience:

Eta's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

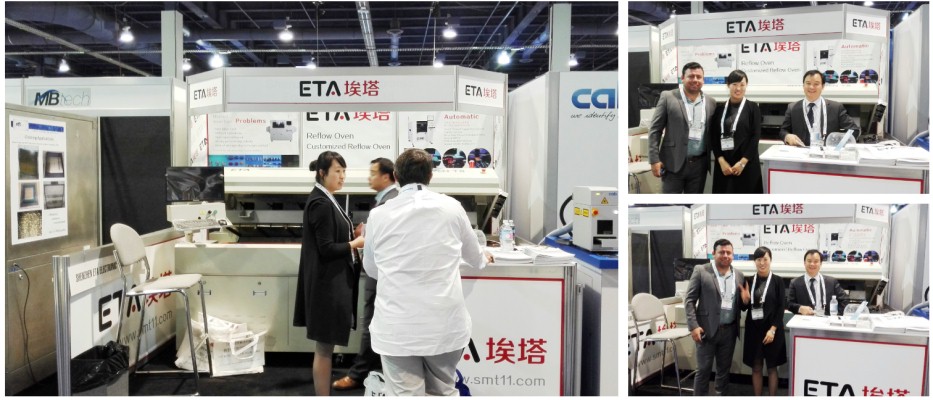

❙ ETA SMT Machine Exhibition

❙ ETA SMT Machine Certificate

❙ ETA Global Service

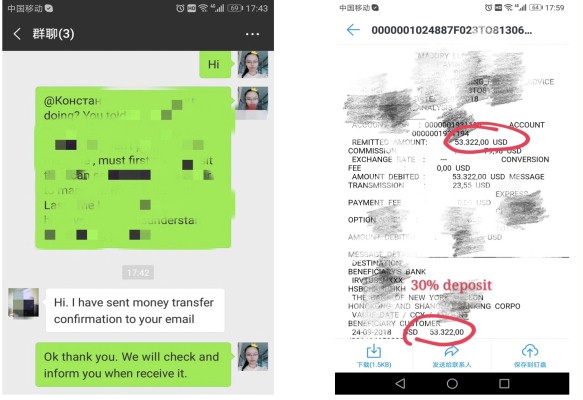

❙ Customers' Feedback

❙ FAQ