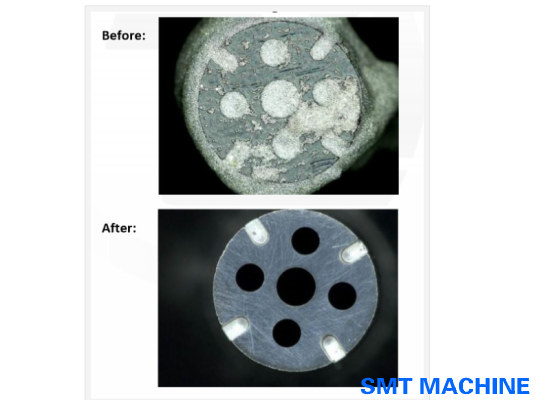

Got Dirty Nozzles?

From: Author:Mark Hardy Publish time:2021-09-11 13:55 Clicks:0

One of the most critical steps to a robust SMT process is having clean nozzles.

No SMT equipment can place components accurately and run efficiently without well-maintained nozzles. If the machine is either unable to pick parts consistently or hold on to the components during the transport from feeder to PCB, defects will result. An increase in defects means a decrease in production! Proper nozzle maintenance is critical for optimal placement productivity.

Are you experiencing any of the following placement problems?

Miss-picks OR

Skewed placements

Then you may have dirty or contaminated nozzles, which require maintenance.

Got Dirty Nozzles. . . Clean them UP!

Not to worry, you can clean them up fast and easy with our nozzle cleaning tool set . . .

it’s quick, easy & effective.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

More details, please contact us:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etaSMT@foxmail.com

SMT Line Automatic, SMT Line Machine, SMT Solder Paste Printing Machine, SMT Printing Machine, SMT Oven, Infrared ic Heater, Small Wave Soldering Machine, Chip Mounter Feeder Yamaha, Chip Mounter Nozzles Washing Machine, LED Automatic Chip Mounter LED660V, PCB Production Line Coating Machine, PCB Conformal Coating Desktop Machine, Coating Spraying Gluing Machine For PCB, V-Cut Aluminum PCB Separator, Cut Bit PCB 0.1 3D Engraving Bit, Soldering Iron For Robot, Mini Robotic Soldering Machine