SMT-PCBA defective product maintenance management method(1)

From: Author:SMT-PCBA defective product maintenance management method Publish time:2021-09-02 10:41 Clicks:0

一. The purpose

Standardize the process and requirements of repairing defective products to ensure the quality of repairing defective products.

二. Scope

This document is applicable to defective products produced during trial production, mass production, and heavy industry in the SMT center.

三. Powers and Responsibilities

3.1 The production department is responsible for intercepting, isolating, marking, and feedback of defective products during the production process, and the maintenance team is responsible for the specific maintenance of defective products.

3.2 The engineering department is responsible for analyzing defective products and giving improvement and control measures, and instructing the maintenance team to maintain

Repair defective products.

3.3 The quality department is responsible for the final judgment of defective products and the supervision of the repair process.

四. Definition

4.1 Defective products: PCBA boards whose appearance, welding, and function fail to meet the relevant quality inspection standards during the production process are called defective products.

4.2 Explanation of terms:

SMT ( Surface Mount Technology)

PCB ( Printed Circuit Board)

PCBA( Printed Circuit Board Assembly)

POP ( Package On Package)

MSD ( Moisture Sensitive Device)

ESD ( Electro Static discharge)

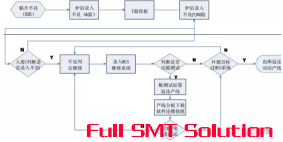

五. Flow chart: