SMT Defect List

From: Author: Publish time:2021-08-31 17:50 Clicks:0

SMT Defect List

SMT Defect List and SMT Troubleshooting (SMT / SMD Problem and Solution)

SMT (Surface Mount Technology), like other SMD Soldering and PCB assembly technology is not ZERO-Defect soldering process. There will always be some or the other defect in any Electronics PCB assembly in both Thru-Hole and SMT.

Here I will discuss some of the most common faults and causes of SMT defects and possible solution and troubleshooting.

Common Faults in SMT:

- Solder balls

- Solder beading

- Bridging

- Open- Insufficient

- Tombstoning

- Unmelted paste

- Excessive filet

- Slump

- Dewetting

- Disturb joint

- Orange Skinning

Solder Balls – Possible cause:

- Solder Paste smearing on underside of stencil.

- What is squeegee pressure?

- Is stencil underside cleaned with a solvent and is solvent still present after cleaning?

- Is stencil proper aligned with PCB?

Solution to Solder Ball Problems:

-

Check squeegee pressure

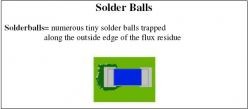

Solder balls = numerous tiny solder balls trapped along the outside edge of the flux residue

- Check for proper gasketting and alignment

- Check if cleaning solvent is completely evaporated before printing

Oxidised paste – Possible cause

- Was paste shipped refrigerated?

- Did paste spend a long time in a hot area?

-

Was old paste returned to jar?

Solder balls = numerous tiny solder balls trapped along the outside edge of the flux residue

- Was jar put back into refrigeration after opening?

- Is alloy sensitive to oxidation?

Solution to Oxidised Solder Paste Problems:

- Run fresh paste from a different lot under same conditions and see if solder bars go away.

Oxidised paste – Possible cause

- Squeegee pressure too high

- Paste gets squeezed out between stencil and board

Solution: Reduce squeegee pressure

Possible cause:

- Drying out of paste after printing

- What is specified tack time of paste?

Solution: Run a PCB with fresh paste and see if problem goes away

Possible cause:

- Too slow ramp up in reflow profile

Solution: Run recommended profile and see if problem stays

Possible cause:

- Too rapid ramp up in flow profile

Solution: Run a slower ramp up profile to give volatiles to evaporate

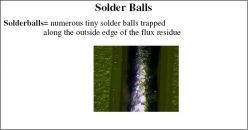

SOLDER BEADS – Possible cause:

-

Reflow profile ramp up slow

Solder beading : solder balls that are alongside a components

- Capillary action draws unreflowed paste away from pad to somewhere under the component, it reflows there and form a bead of solder which comes out from under the component side.

Solution: Run a more rapid ramp up profile of 1.5 Degree Celsius to 2.5 Degree Celsius per second.

Possible cause:

- Excessive amount of solder paste on component pads

- What is stencil thickness?

- Are apertures reduced?

- Dispense time for a dot?

Solution:

- Reduce aperture size of stencil or use thinner stencil

- Use smaller needle and/or reduce purge time on dispenser

Possible cause: Paste smearing on underside of stencil

- What is squeegee pressure?

- Is stencil underside cleaned with a solvent and is solvent still present after cleaning?

- Is stencil properly aligned with PCB?

Solution:

- Check squeegee pressure

- Check for proper gasketting and alignment

- Check if cleaning solvent is completely evaporated before printing

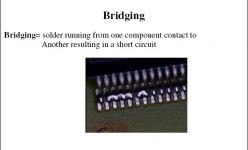

BRIDGING – Possible Cause:

-

Cold slumping

Bridging = solder running from one component contact to another resulting in a short circuit

- Is paste flowing apart after printing, height of deposit reduces and surface increases.

Solution:

- Check viscosity of paste, too low viscosity may result in cold slumping

- Check print speed, too rapid print speed may result in shearing of paste and degrading its thickness

-

Check temperature in printer, too high temperature brings viscosity down

Bridging = solder running from one component contact to another resulting in a short circuit

Possible Cause:

- Hot slumping

- Is paste flowing apart during ramp up part of reflow profile

Solution: Shorten duration of ramp up cycle in reflow profile

Possible Cause:

- Paste smearing on underside of stencil

- Paste can be outside pad area and form solder balls between two component leads resulting in a bridge

Solution – Reduce squeegee and check pcb-stencil alignment and gasketting

Possible Cause:

- Excessive solder paste being deposited on the pads

- While placing a component on the pads the paste is smeared out and may form a bridge to an adjacent pad

Remedy:

- Reduce amount of solder paste

- Increasing print speed may

- Reduce stencil thickness

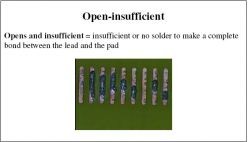

Open-insufficient – Possible cause:

Opens and insufficient = insufficient or no solder to make a complete bond between the lead and the pad

- Scooping during printing

- Excessive squeegee pressure on a polypropylene squeegee may cause scooping

Remedy: Reduce squeegee pressure or use a harder durometer type of squeegee or use a metal squeegee

Possible Cause: Blocking of stencil aperture with dried up paste

Remedy: Unblock apertures and clean stencil

Possible Cause:

Opens and insufficient = insufficient or no solder to make a complete bond between the lead and the pad

- Foreign material on solder pad

- Was solder mask printed on pad?

Remedy: Use another PCB

Possible Cause:

- Too high squeegee speed

- Paste cannot get into the apertures

Remedy: Reduce squeegee speed

Possible cause: Solder paste viscosity and/or metal content too low

Remedy: Check viscosity and metal content

TOMBSTONING

Tombstoning = chip type components standing up on one end after reflow caused by unequal forces on the components end

Possible cause: Unequal placement of components on pads prior to Reflow results in unbalanced solder forces.

Remedy: Check if placement equipment places properly.

Possible cause: Unequal heat sink i.e. ground planes inside PCB layers may draw heat away from pad.

Remedy: Increase soak time (plateau) or reflow profile so that all components are on.

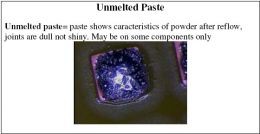

UNMELTED PASTE – Possible cause:

- To cold reflow profile

- Solder paste cannot melt completely

Unmelted paste = paste shows characteristics of powder after reflow, joints are dull not shiny. May be on some components only

Remedy: Check reflow profile, make sure peak temperature and time above liquids (183C) are high enough and soak (plateau) is long enough.

Unmelted paste = paste shows characteristics of powder after reflow, joints are dull not shiny. May be on some components only

Excessive Fillet

Possible cause: Too much solder paste deposited on pads

Remedy:

- If excess solder occurs on all components reduce overall stencil thickness or reduce dispenser purge time

- If excess solder occurs on some places only reduce stencil thickness or dispense purge time for these components only

Excessive fillet = bulbous appearance of joint where outlines of the leads are obscured by the quantity of solder on them

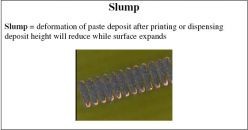

Slump Cold Slump – Possible cause:

Viscosity of paste to low or metal content to low

Slump = deformation of paste deposit after printing or dispensing deposit height will reduce while surface expands

Remedy: Use different type of paste with higher viscosity or higher metal content

Possible cause: Paste came in contact with a cleaning solvent or other alien product

Remedy:

- Make sure there are no solvents presents after cleaning the screen

- Never try to revive the paste by adding some compound

Possible cause:

Slump = deformation of paste deposit after printing or dispensing deposit height will reduce while surface expands

- Squeegee pressure to high

- Paste is shearing due to excessive pressure applied to it thickeners in paste are destroyed

Remedy: Use new paste and reduce squeegee pressure

Possible cause: Temperature of paste is too high while printing or dispensing

Remedy:

- Check temperature inside printer

- Reduce pressure on squeegee

- Reduce on pressure on syringe when dispensing

Hot Slump

Possible cause: Too slow ramp up in reflow profile

Remedy: Increase ramp up temperature, make sure to have a ramp up between 2 Degree Celsius to 3 Degree Celsius per second

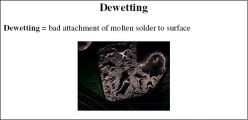

DEWETTING – Possible cause:

Dewetting = bad attachment of molten solder to surface

- Unwanted material on surface which prevents solder from attaching to surface, i.e. solder mask, fingerprints or oxides.

Remedy:

- Clean boards first

- Use different batch of boards

Possible cause:

Dewetting = bad attachment of molten solder to surface

- Bad alloy in HAL process, i.e. too much Cu elevates melting point of HAL alloy

remedy:

- Increase peak temperature in reflow

- Use different batch of boards

Disturbed Joint Possible cause:

A source of vibration that is transmitted through the pcb during the liquids state of the reflow profile

Remedy:

- Find and fix source of vibration

- Adjust reflow

Disturbed Joint = dull, rough appearance of solder in an alloy that is normally bright and shiny

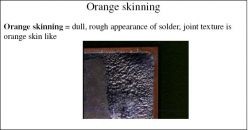

Orange skinning – Possible cause:

Orange skinning = dull, rough appearance of solder, joint texture is orange skin like

- Too high in peak zone

- Residue is burned or rosin was cooking

Remedy:

- Lower peak zone temperature

Possible cause:

- Too long exposure to temperatures between activation temp and reflow = (depending on alloy)

Remedy:

Orange skinning = dull, rough appearance of solder, joint texture is orange skin like

- Shorten time in soak or lower soak temperatures

Possible cause:

- Preheating too high

Remedy:

- Lower preheat temperatures

Use Nowadays SMT Equipment can reduce the SMT Defect to a very low level:

Automatic SMT Production Line:

PCB Loader➡SMT Stencil Printer➡PCB Conveyor➡SPI➡Pick and Place Machine➡AOI➡SMT Reflow Oven➡AOI➡PCB Unloader➡DIP Component Insert Line➡Wave Soldering Machine➡THT PCB unloader