Juki Rs1 Pick And Place Machine

From: Author:SMT Pick And Place Machine Publish time:2021-09-14 11:08 Clicks:0

Juki Rs1 Pick And Place Machine

Basic Description

RS-1R, as the new generation of JUKI pick and place machine, its base frame has been redesigned, thus, its mounting speed has been also improved greatly, which is more faster compared to the RS-1.

Feature

1. Nozzle

- For upgrading the track ability and management, JUKI has put RFID tags onto all the nozzles. Besides, the operator can monitor the maintenance for nozzles

- The nozzles track ability function.

2. Large Nozzle ATC

- Changeable ATC plate supports nozzles up to 7*28 mm. It is available for heavy components or large nozzles.

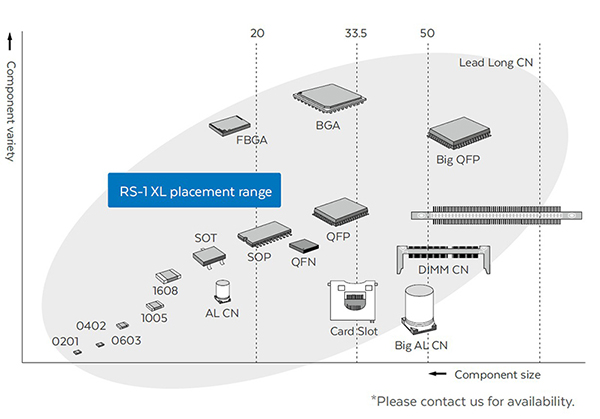

3. Broad Range Of Component

-

RS-1R supports components from 0201 (metric) to 74 mm square or 5*150 mm rectangular parts.

The maximum height for component of RS-1R is 25 mm.

Juki Rs1 Component Range – Photo Source:Juki

4. Optimum Line Balance and Highest Output

- Changing the RS-1R functionality does not demand a head replacement. Equipped with the innovative head, it is able to be adjusted according to the assembly needs.

- Brilliant head design enables it to greatly improve the placement speed. Furthermore, it will become more flexible for complicated PCBs with lots of large components.

5. Self-optimized SMART Head

- “Takumi head” can automatically optimizes its height between 6 different positions on the basis of the component height. Tact time is optimized by maintaining the head as close to the printed circuit board as possible for the components mounted.

- New Dynamic Height 8 nozzle placement head automatically adjusts height to improve the placement speed.

- This head adjusts automatically on the basis of the components to be mounted from 1 mm to 25 mm in 6 different positions (1 • 3 • 6 • 12 • 20 • 25 mm).

- Broad range of supported components such as SOP, QFP, PLCC, BGA and many more. Sizes can be from 0201* (metric) to 50 mm square.

Takumi Head Video

6. Optimum Line Balance and Highest Output

- Changing the RS-1R functionality does not demand a head replacement. Equipped with the innovative head, it is able to be adjusted according to the assembly needs.

- Brilliant head design enables it to greatly improve the placement speed. Furthermore, it will become more flexible for complicated PCBs with lots of large components.

Specification

| Board Size | Max. 650x370 mm (single clamping) | |

|---|---|---|

| Max. 950x370 mm (double clamping) | ||

| Max. 1,200x370 mm (double clamping) | ||

| Component height | 25 mm | |

| Component size | 0201 (metric) - 74 mm / 50x150 mm | |

| Placement Speed | Optimum | 47,000 CPH |

| IPC9850 | 31,000 CPH | |

| Placement accuracy | +/- 0.035 mm (Cpk grater than 1) | |

| Feeder inputs | max. 112 | |

| Power supply | 200 - 415 VAC, 3-phase | |

| Apparent power | 2.2 kVA | |

| Operating air pressure | 0.5 +/- 0.05 MPa | |

| Air consumption | max. 50L / min |

Dimension

| Dimension (LxWxH,mm) | 1,500x1,810x1,440 | |

|---|---|---|

| Weight (kg) | 1,700 |

Keywords:

SMT Machine Production Line LED, AutomatIC SMT Production Line, Semi AutomatIC Stencil Printer, Semi AutomatIC Printer Stencil, Vacuum Reflow, Reflow Oven, Flex System In Wave Soldering Machine, 3 Head PICk And Place Capping Machine, SMT PICk And Place Machinetabke Top Meachin, SMD PICk And Place Machine Juki Nozzal, Copper Clad Laminator PICk And Place Machine, SMD PICk And Place Mini Machine Setup, Hct-600Sv PICk And Place Machine, Small Vacuum Pump For PICk And Place

, Coating Machine For PCB, SMT Conformal Coating Machine, PCB UV Coating Machine, PCB Board Coating Machine, PCB Machine Route, Blind Routing PCB