IGBT power modules (inverters) are needed to convert electricity from one form to another so that the electricity can be conveniently and safely used by many of the things we use in our everyday lives; including: air conditioners, refrigerators, electric cars and more.

Learn more about IBGT, including how they work and what it takes to manufacture them below.

What’s an IGBT?

IGBT is the short form of Insulated Gate Bipolar Transistor. It is an three-terminal power semiconductor device primarily used as an electronic switch. These devices- integrated as part of an IGBT power module- are ideal for today’s electronic devices because of their ability to quickly turn the flow of power flow on/off.

An IGBT power module is the assembly and physical packaging of several IGBT power semiconductor dies in one package.

IGBTs are found in: electric cars, variable-frequency drives (VFDs) trains, variable speed refrigerators, lamp ballasts, air conditioners, military applications and just about any electronic devices that requires high-speed switching of current.

What does an IGBT module do?

An IGBT power module functions as an electronic switching device allowing the current to switch from DC to AC. By alternate switching direct current (DC) can be transformed to alternating current (AC) and vice-versa.

Imagine you’re a DC battery and someone taps you on the shoulder and asks you to produce AC instead. How would you do it? If all the current you produce flows out in one direction, what about adding a simple switch to your output lead? Switching your current on and off, very rapidly, would give pulses of direct current. To make proper AC, you’d need a switch that allowed you to reverse the current and do it about 100 times every second. Visualize yourself as a human battery swapping your contacts back and forth over 6000 times a minute. Now that’s a lot of switching. Luckily for us, the IGBT power module can easily take over that job for us. . . .

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technICal team in Asia, Europe, AmerICa, AfrICa, and Australia.

More details, please contact us:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etaSMT@foxmail.com

Gee… I’m kinda tired. How about you?

This power conversion is important for the applications to function correctly. For example, in order to drive an electrical motor, 3 phase AC current is needed. While on the other end, all electrical energy storage systems (batteries) need DC current. IGBT modules play an integral role in making this happen.

IGBT and Electric Cars

In electric cars, the IGBT power module is considered the ‘heart’ of the electrified drive train.

Similar to a heart distributing energy throughout our bodies, the power module functions as the human heart in the electric drive train for electric and hybrid-electric vehicles. In the electric drive train, the power module distributes and converts the DC current from the electric vehicle battery, to AC current to be used in the electric motor driving the vehicle propulsion system. That makes the power module a critical component in improving energy efficiency and battery range for electrical cars.

What’s inside an IGBT Power Module Unit?

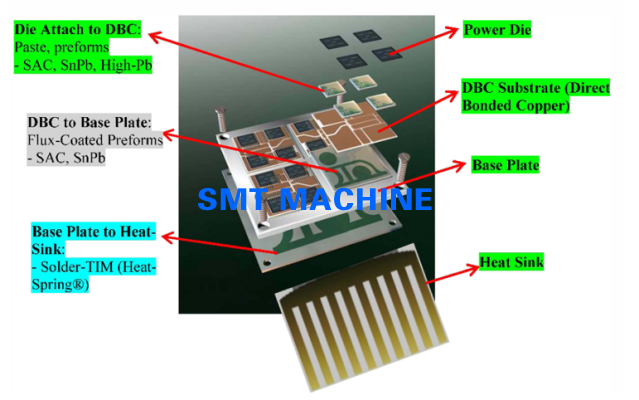

The image below is an exploded view of the typical elements of an IGBT module, which may include: several power module boards, plastic housing, heatsink, layers of silicone and/or glue, and a gel layer (to help with heat dissipation). All of this is then placed inside the housing assembly and the pieces of the assembly are attached together to create the final assembled unit.

Let’s break down these elements and talk about some of the manufacturing challenges.

Power Module Board

The power module board, which is typically a Direct Bonded Copper substrate (DBC substrates are commonly used in power modules, because of their very good thermal conductivity. ) require multiple types of die and solder preform attach. Processes may include: IGBT die attach, diode die attach, SCR (Silicon Controlled Rectifier) / Thyristor die attach, solder preform attach, and capacitor and resistor placement.

Direct Bonded Copper Example showing multiple die types

What would be some of the challenges of manufacturing a board like this?

- Fragile die and substrate handling

- High-Mix component types

- High throughput demand

Assembly Line For TV, Reflow Oven Soldering Machine, Auto Wave Soldering Machine, Pick And Place Ampoule Machine, SMT Mini Pick And Place Machine, LED Light Pick And Place Machine, Pick And Place Composants Electronics Machine, Automatic Pick And Place Sheet Machine, Table Top Pick And Place Machine, Stencil Cleaning Machine 850, SMT Line Auto Aqueous Stencil Cleaning Machine, Pneumatic Stencil Cleaner Machine And Stencil Wash, Stencil Washing Machine, Fixtures Ultrasonic Cleaning Machine, , Soldering Robot PCB SMD, Desktop Toy PCB Automatic Soldering Robot